Industrial Shredder

Everyday, there is a lot of waste generate in the world, and some of these waste is too big to recycle or transport, for example: scrap tire, scrap plastic, E-scrap…inorder to recycling and transport easily, usually, they will be shred into a small particle before disposal.

I. About Shredder.

Shredder is a machine to reduce the size of material through the way of shearing. Basically, According to different requirement of production, We can find four kinds of shredders by this time. Even it will be in different structural profile as below, but inside, their basic structure of shaft is similar, so we can categorize industrial shredder into four sorts .

Shredder Types:

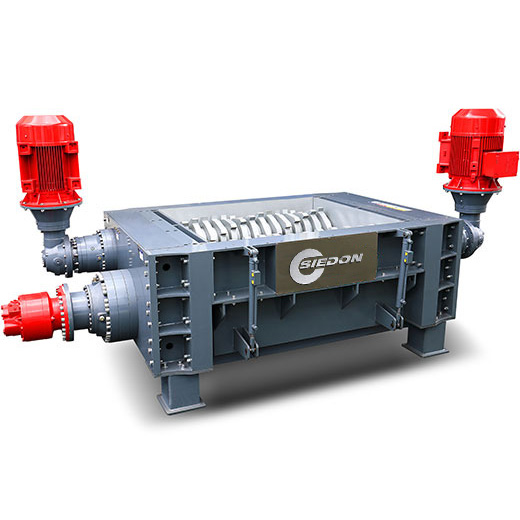

Twin shaft shredder

Low-speed, 26/24 run/pm, high-torque, two shafts, shear shredder. Recommended for metals, soft plastics, tires, product destruction, or any diverse and contaminated materials where particle size variation is allowed. (Particle size about: 30mm*80mm*20mm).

Four shaft shredder

Low-speed, 26/24 run/pm, high-torque, four-shaft shredder. Especially suited for applications such as electronic scrap, tire shredding, alternative fuel production, and reduction of contaminated materials where uniform, small to medium particle size is desired. (Particle size about: 30mm*80mm*20mm).

Coarse shredder

Low-speed, high-torque, multi-material reduce. A high-capacity solution ideal for construction and demolition and for volume reduction of bulky waste containing metal and abrasives. Particle size is coarse.

II. Purposes of using Shredder

1. Saving transportation costs. Some volume of scarp is very big. For example: furniture scarp, wood scarp…If take it to the landfill directly, the cost of transport will be very expensive. But if shred it before, the volume can be reduce to 30%~50%, then it will not take up too much space, thus saving costs.

2.Reuse the plastic scarp. most of plastic can be reuse, it is just make it into small particle then put it into the extruder and palletize it. But the point is: the volume of scarp need small enough to melt by the extruder. So it must be shred before palletize. Plastic take a very import position in our life, reuse the plastic is a big market. And the shredder can be helpful and efficient for this work..